If Businesses Are Producing at Capacity

Production capacity at the beginning of the year Average annual capacity of the equipment introduced during the year Average annual capacity of the equipment removed during the year. Depending on the business type capacity can refer to a production process human resources.

What Is Production Capacity And How To Calculate It Mrpeasy

Answer Lower interest rates.

. The companys capacity utilization rate is 50 2000040000 100. Suppose a factory has 8 sewing lines and each line has 25 machines. Excess capacity is calculated using the minimum long-run average cost.

This is the classic strategy and if you have just a couple of bottlenecks increasing capacity may be quite. For example if you produced 20000 gizmos per week but half of the time your people were idling then you cannot use the 20000. Capacity planning determines how much capacity your company needs to meet varying customer demands.

Enter the relevant data in the other fields such as Starting Time Ending Time Quantity and Scrap. If businesses are producing at capacity and the nation is experiencing almost full employment a very low rate of unemployment - less than 2 the Fed may decide to. The measurement is done in a way that we can adjust our production capacity according to the demand from the market.

The objective manifestation rule is used to argue the enforceability of a promise that. Answer Lower interest rates. If businesses are producing at capacity and the nation is experiencing almost full employment a very low rate of unemploymentless than 2 the Fed may decide to.

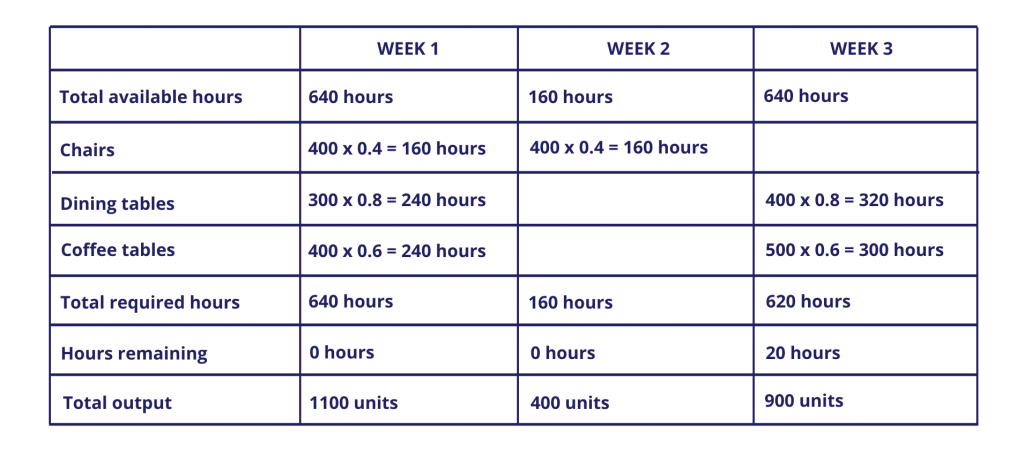

Productive capacity can change eg. The following are illustrative examples of production capacity. The capacity is calculated over days or weeks or months.

There is no excess capacity in the long run for perfectly competitive markets. In the Type field enter the type of the capacity either Machine Center or Work Center that you are posting. It tells you if your organization has enough people with specific skill sets whether additional.

Choose the Post action to post the capacities. MxAPS from Insight Works is an advanced finite capacity planning and scheduling app that generates a schedule that you can actually use on the shop floor. Total 200 machines and the working shift is 10 hours per day.

Often production schedules are managed by one or two people who really understand the process. If businesses are producing at capacity and the nation is experiencing almost full employment a very low rate of unemployment - less than 2 the Fed may decide to. Question 13 If businesses are producing at capacity and the nation is experiencing almost full employment a very low rate of unemployment - less than 2 the Fed may decide to.

This enables companies to calculate the production capacity. Hence for a system working at full capacity it is the average quantity produced in a given time period. View the full answer Previous question Next question.

1000 cars per month. Production Capacity Formula. The average annual production capacity is defined as.

Many business decisions are based on assumptions about the production capacity of your business. Hence it is not a short-run occurrence. Capacity can be defined as.

Prices of products will remain low for consumers when a firm is producing below capacity. MxAPS takes this knowledge and experience and automates the process. When a machine is having maintenance capacity is reduced.

Increase interest rates. Production capacity is the volume of products or services that can be delivered by the operational resources of an organization. The mathematical formula for calculating capacity utilization is.

Excess capacity is a situation where a firm does not produce at optimum or ideal capacity mainly because of reduced demand. Production capacity in pieces Capacity in hours60product SAMline efficiency For Example. The maximum output that a business can produce in a given period with the available resources Capacity is usually measured in production units eg.

Field enter the number of the machine center or work center. The cost of purchasing or renting equipment is not reliant on production so excess capacity can be a problem for. A capacity cost is an expense incurred by a company or organization in order to provide for or increase its ability to conduct business.

Question 21 If businesses are producing at capacity and the nation is experiencing almost full employment a very low rate of unemployment - less than 2 the Fed may decide to. For example your decisions to purchase new equipment take on new business add another shift or relocate your business will all be based on your actual or perceived level of capacity. Answer Lower interest rates.

Capacity is the maximum output level a company can sustain to provide its products or services. Manufacturers to start producing critical. Resources include factors such as land labor facilities infrastructure and machines.

The consequences of not understanding capacity can therefore. Once you have above information use following formula to calculate production capacity. Production capacity is defined as maximum production or output which can be produced in business with the help of available resources.

Example of Capacity Utilization Suppose XYZ Company is producing 20000 and it is determined that the company can produce 40000 units. View full document. The current pandemic-related shortages have fueled calls from political leaders of both parties for US.

If your system is working at less than capacity however you cannot take the total production quantity. Excess capacity refers to a production capacity which falls below an industrys production capacity.

Understanding New Power Sharing Economy Business Management Program Management

Production Capacity Meaning Importance Factors Example Mba Skool

Comments

Post a Comment